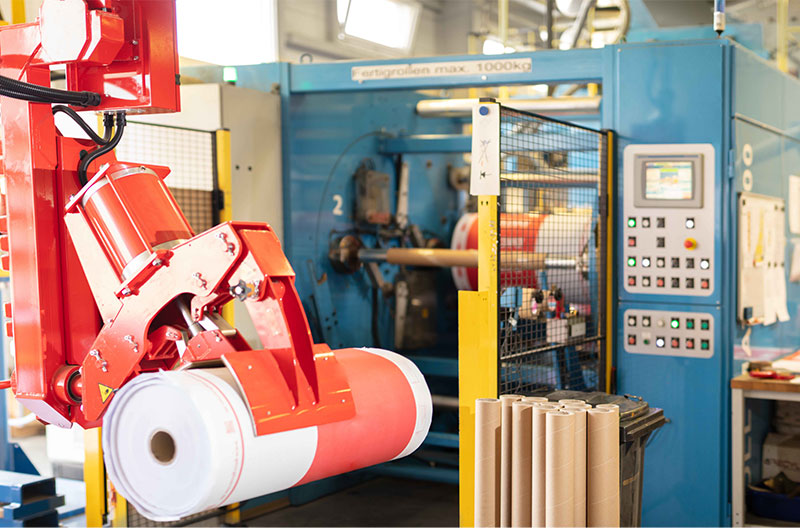

Flexographic printing

what you should know about the possibilities:

It is important to get to know and understand how to use modern flexographic printing. With innovative machines, we can make almost everything possible for your various applications; starting with printing inks and coatings, when foodstuffs have indirect and direct contact with the packaging material. This even extends to technologies that we can use to apply heat-resistant coatings for oven applications, for example. We also know our stuff when it comes to processing barrier coatings for the substitution of PET film. It goes without saying that we use solvent-free printing inks for flexographic printing (EU Directive 2019/904), which also meet the strict requirements of the FDA.

As well as maximum flexibility:

• Print up to approx. 110 cm width

• Paper and cardboard with a basis weight of 45 to 500 g/m²

• Materials up to 1 mm thickness

• Numerous inner sleeve diameters possible

• Up to 6 printing units

• Printing from large roll to large roll – max. 1300 mm diameter

• Various inline printing units in small roll slicing machines

Ihr gewünschtes Produkt ist nicht dabei? Wir helfen Ihnen gerne weiter